SHARRIX – FMEA (FAILURE MODE EFFECTS ANALYSIS) SOFTWARE

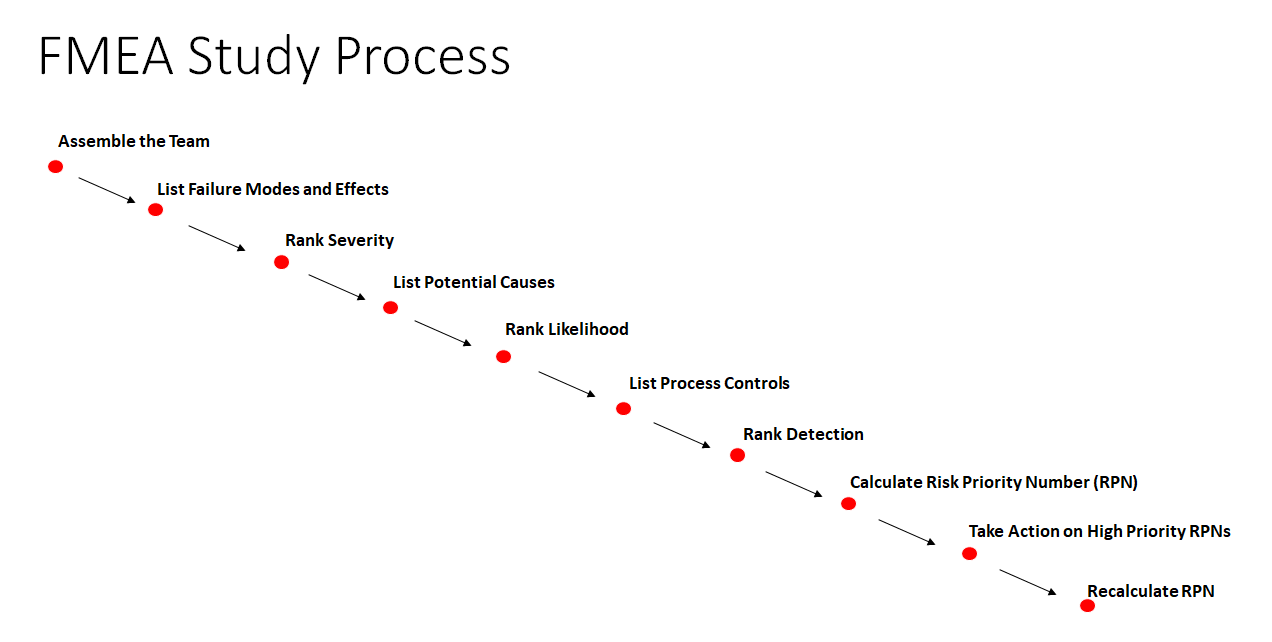

Failure Mode & Effects Analysis (FMEA) studies are used to systematically identify and understand the potential causes of failure, consequential effects and risks to users of commercial goods and products. The results of these studies help prioritize actions, enable informed decision making, and allocate resources to reduce risk to acceptable levels. These studies can be both standards and regulatory program driven for example;

- ISO 9001: 2015 General Manufacturing Quality Management Systems,

- AS 9100: 2016 Aerospace Quality Control,

- ISO 13485 Medical Quality Management Systems,

- IATF 16949: 2016 Automotive Quality Management Systems.

Performed by an experienced and appropriate team, systems must be in place to conduct the study, track related engineering documents, recommendations, document resolutions, and take timely corrective actions.

Improve teamwork with easy to use and highly flexible FMEA Study Software.

Our cloud based software marks the end of the need for desktop installed stand alone or client server FMEA software applications. Attracting and keeping the next generation of engineers requires cutting edge software that supports team collaboration. Sharrix software makes it easy to bring your team together to identify and assess the risks that pose significant potential liability to your organization. Risk reduction actions can be assigned and tracked on your mobile device and/or existing email system ensuring closed loop Corrective and Preventive action is achieved on every action task assigned.

Our powerful software is designed to keep your costs low, drive team collaboration, create workflows your way, connect with your existing in-house systems, while adjusting quickly to changes with our patent pending dynamic risk modeling capabilities. Attracting and keeping the next generation of engineers requires software designed to bring your quality risk management team together with leading metrics dashboards that include,

- FMEA actions open, overdue, completed,

- FMEA’s Scheduled vs. completed,

- Status of FMEA recommendations,

Below are benefits of Sharrix Software

Improve Teamwork

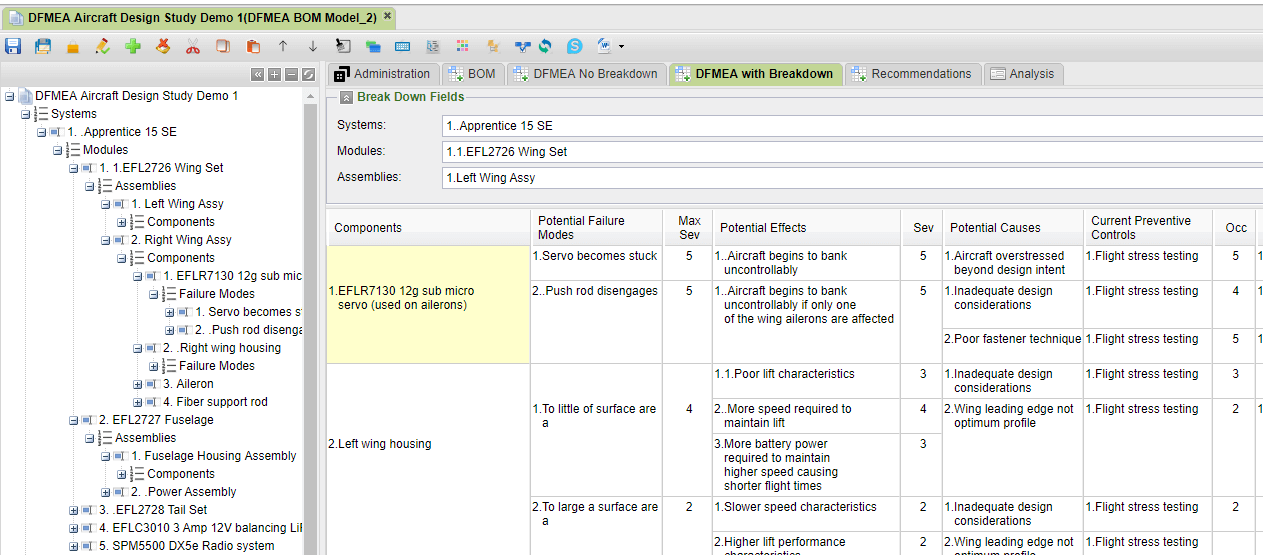

- Support standardization and consistency of FMEA (DFMEA, PFMEA, FMECA) studies

- FMEA recommendations can be directly linked to the Action Tracking workflow for immediate assignment to the right people in your organization

- Automate workflow processes to align with your organizations performance standards

- Reduce time needed by study leaders, scribes, and participants to conduct, document and close out studies

- Standardized Risk Libraries that keep language common across studies and speed access to Product Materials, Manufacturing SOP Steps, Physical Design, Equipment, Control Systems, Maintenance Practices, and Protective Measures

- Easily work with Sharrix Partners (consultants, auditors, and other technical experts) by exporting and importing studies

Leverage Existing Systems

- Open Architecture – and a flexible set of deployment options, from SaaS to customer site deployment.

- Quickly connect with ERP, PLM, BOM, Incident, Warrenty, Maintenance, and others.

- Collaboration with document management software to quickly access Operating Procedures, control documents, procedures and other content.

- Display risks with leading design and 3d visualization software applications.

- Keep studies standard by linking with the Master Management Strategy – company hierarchy, equipment, products, and process information.

Measure Results

- Capture performance measures within and across FMEA studies and risk reduction activities that document progress against performance standards.

- Report results across the organizational hierarchy process, product, equipment, facility, business unit, enterprise.

- Improve the development of operating procedures, training, mechanical integrity program, and emergency response plans

- Qualitative and Quantitative FMEA models are configurable for RPN calculations using either 2 or 3 input variables.

Reduce Costs

- Eliminate IT shadow spend from multiple FMEA, DFMEA, PFMEA desktop applications license and maintenance fees.

- Lower cost of future studies – planning, meeting, documentation, and follow up time

- Reduce the cost of hardware and maintenance with cloud delivery

- Reduce preventable problems. Better use of risk studies results in higher reliability, better quality, increased safety, and enhanced customer satisfaction.

Increase Visibility

- Know and show actions are completed for each study with mobile task management.

- Display risks through Engineering software tools (e.g. Intelligent P&ID and Plant 3D Simulation).

- See information about products, processes, equipment and performance.

- Provide reports across a knowledge base of studies and lessons learned from past studies.

- Preserve the wide range of professional knowledge bases available to enable you to complete more thorough research and analysis.

Quickly Adapt to Change

- Business Oriented, Process Based

- Utilize Dynamic FMEA Risk Modeling to quickly improve your study approach

- Software and Hardware standards are always changing use software designed to operate in a multi device environment.

- Adjust dates for risk reduction action completion based on budget approval plans

- Empowers your team with needed analysis such as Design Verification Plans (DVP&Rs), Design Reviews Based on Failure Mode (DRBFMs), Process Flow Diagrams, Process Control Plans (PCPs) and others